Tailored Automation Solutions

for Your Industry

Electrical Design

We will come up with an electrical design that will be optimal for your needs. On a conceptual level, design is the key to scope of the project and its execution. The Mikro Kontrol design always enables the fastest and smoothest execution without having to buy any non-necessary equipment.

Electrical design is often divided into sub-categories. These groups of activities are:

Conceptual design

Conceptual design is the first step in designing a new system. In it, the Mikro Kontrol design team helps the client identify and examine its exact needs more clearly. Alternative solutions are compared and evaluated against one another. Alternatives for potential solutions are scrutinized. System specifications (e.g. technical requirements and environmental targets, as well as forecasting of investment costs) are considered and defined.

Basic design

Basic design starts with an overall system configuration. It includes all the necessary schematics and layout diagrams. In this step, all the performance specification requirements are included. Basic design represents a general framework for further steps to build a more detailed electrical design on.

Detailed design

Detailed design represents the most serious and comprehensive basis for the implementation phase of a project. Detailed design includes precise specifications for each system interface and function. It is key to the successful implementation of all project phases, including cabinet assembly, software development, and commissioning.

As-built design

As-built design comes in a later stage of a project. It is done upon completion of commissioning. It represents a summary of all the functional documents. It is highly relevant for maintenance purposes.

Design review

Design review represents a final examination of the whole documentation. It consists of various checks. They include:

- Checks of compliance and rules at the site

- Checks of compatibility with law and regulations

- Checks of quality

- Checks of accuracy of technical and technological solutions

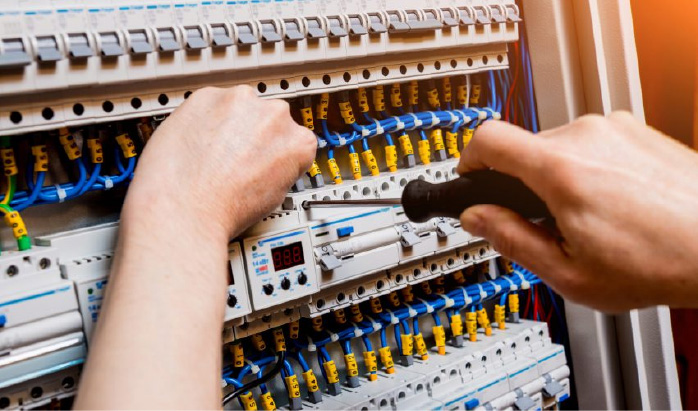

Cabinets Assembly

In the Mikro Kontrol workshop, we assemble cabinets customized to fit the needs of our clients. They include control cabinets and LV power cabinets, or MCC cabinets. Control cabinets embed PLCs and DCS. The assembling includes the mounting of the equipment into cabinets, the equipment wiring, as well as the equipment labelling. We assemble our cabinets according to the latest European standards, LV regulations, safety regulations, and EMC regulations. We can provide CE marking for every cabinet we assemble.

We embed equipment into E-Houses for special applications, where it is a part of the turnkey solution. This also includes such equipment as transformers, and mid-voltage equipment. We use mid-voltage switchgears manufactured by top global producers.

- PLC and DCS cabinets

- LV Cabinets

- Drives and MCC cabinets

- E-houses assembly

Application Software

Our application software solutions are based on:

PLC

PLC is most suitable for sequential and discontinuous processes, typically in material handling machines and packaging machines.

DCS

DCS is indispensable for industrial process plants such can be found in metal processing, power and chemical industries, cement production, and sugar processing.

HMI and SCADA

HMI & SCADA help with visualization of industrial processes and data storage with checks of history of changes.

Site Management & Supervision

Site management

Overseeing operations on a day-to-day basis and ensuring that everything is done safely, on time, and within the allocated budget.

Coordination of all the activities with the customer’s personnel.

Mounting supervision

DCS is indispensable for industrial process plants such can be found in metal processing, power and chemical industries, cement production, and sugar processing.Acceptance of equipment delivered to the customer’s site.

Quality checks and control of installations are being performed.

Testing & Commissioning

Commissioning is a process that ensures that all the electrical and mechanical components are designed, installed, tested, and set up according to the operational requirements as defined by the Customer (an OEM, an EPC, or an End User). Commissioning involves a set of engineering techniques and procedures to check, inspect and test all the functions and other operational components of the project.

FAT (Factory Acceptance Test)

Factory Acceptance Test (FAT) is a process, done within the Mikro Kontrol workshop, that evaluates the equipment during and after the assembly process. It verifies that the process and activities are built and operate according to the design specification.

No-voltage commissioning

Individual electrical components, and whole cabinets are carefully checked and tested without voltage, to ensure safe testing with voltage at a later stage.

Voltage commissioning

Individual sensors, actuators and other electrical components are being carefully checked. Following all the checks, the whole system is tested with voltage to ensure its smooth operation.

Functional testing

The next step after voltage commissioning is the functional testing, done on-site in two stages. Firstly, without load, and then as the initial run with load (optimization period). Functional testing without load tests ensures each mechanical and electrical function as intended by design.

Initial run

After the functional testing is completed, the initial run is set off. In this phase, the load is increased gradually, up to its full required capacity.

After-Sales Support

Following the project, we offer our clients two additional services: training and maintenance. We can train you in better managing your electrical equipment. Our engineering team can also maintain it for you.

Contact Us for Tailored Solutions!

We operate across diverse industries, tailoring automation and control systems to meet your unique needs.

If you don’t see your industry listed here, don’t worry—contact us to find out how we can help enhance your operations.